Softgel & capsule Vision Inspection

Machine

.png)

.png)

The softgel & capsule vision inspection system is an inspection device that rotates softgel capsules 360 degrees and captures high-speed images to perform a comprehensive inspection.

It detects various defects, including capsule size, shape, foreign particles, bubbles, printed characters, and internal tablets.

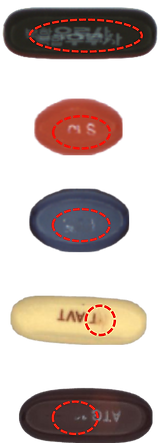

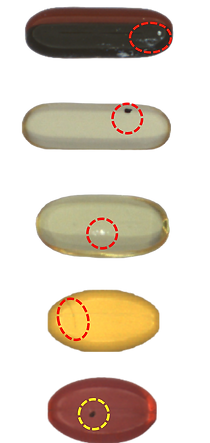

Bubble inspection

The softgel & capsule vision inspection machine detects defects by inspecting internal bubbles and film bubbles within the softgel capsules.

The bubble size can be set in the recipe, allowing customers to adjust the yield according to their specific requirements.

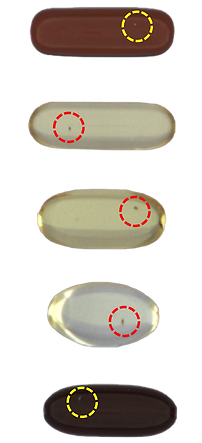

Micro-Foreign

The softgel & capsule vision inspection machine detects defects by inspecting foreign particles on the surface of softgel capsules.

The size of foreign particles can be set in the recipe, allowing customers to adjust the yield according to their specific requirements.

Size & Shape

The softgel & capsule vision inspection machine detects defects by inspecting the size and shape of softgel capsules.

The size range and shape accuracy can be set in the recipe, allowing customers to adjust the yield according to their specific requirements.

Printed text

The softgel & capsule vision inspection machine detects defects by inspecting for issues such as faded or erased printed characters on softgel capsules.

The matching rate with the correct printed characters can be set in the recipe, allowing customers to adjust the yield according to their specific requirements.

Defects Type

Size & Shape

Printed Text

Spot

Outside

Particle

Inside

Particle

(Only transparent)

Inside

Bubble

(Only transparent)

Outside

Bubble

Scratch

Specifications